Loaders are one of the most popular machines used by the construction industry in New Zealand – a workhorse of the job site.

Fulton Hogan has been trialling an electric loader at their Reliable Way asphalt plant since December 2023, and have shared what they have learnt to help other organisations to benefit from the cost and emissions savings of going electric.

Project summary

Company: Fulton Hogan

Industry: Construction

Site region: Auckland

EECA co-funding: Low Emission Transport Fund

Year of funding: 2023

Fulton Hogan’s fully electric 20-tonne Volvo JL120 loader is the Southern Hemisphere’s first medium-sized, fully electric Volvo loader.

Working with Volvo distributor TDX, the company is running a trial to compare the electric loader with a 20-tonne diesel Volvo L120H across three diesel price points.

This loader is 1 of 3 that TDX and Volvo are trialling with different customers, through a project co-funded by EECA’s Low Emission Transport Fund. This trial is a step towards making the loader commercially available.

When you get a new toy, you go right, let’s find the hardest job we do and give it heaps. And that’s what we’ve done. It out-performs.

Running costs slashed

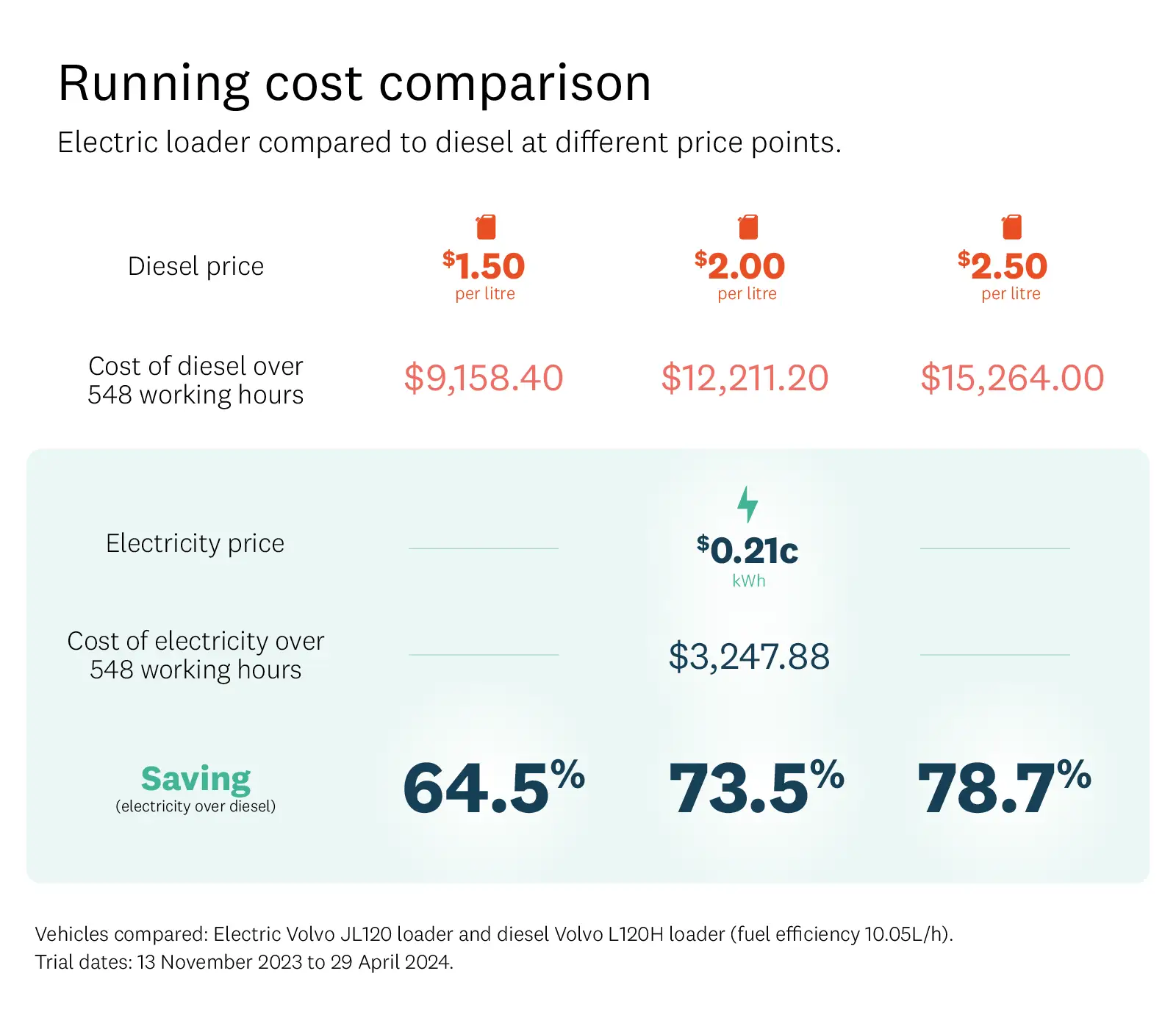

As part of this trial, Fulton Hogan compared the cost of running the new electric loader to the cost of fuelling an equivalent machine with diesel, which found a significant saving in running costs.

They measured the loader’s electricity use from 13 November 2023 to 29 April 2024 (548 working hours) at Fulton Hogan’s Reliable Way Asphalt Recycling Plant. The machine was used to load stockpiled recycled asphalt into the plant, bailing out processed product and stockpiles, and to load trucks and trailers.

The cost to power it was compared to the diesel L120H’s fuel efficiency average of 10.05L/hr under the same conditions. Diesel costs were set at three price points to provide a broad comparison.

The electric loader proved significantly cheaper to run, even compared to the cheapest diesel price point. Not only that, but the electric loader also offered greater efficiency, using the same amount of energy to power a larger 6.5t bucket compared to the diesel’s 4-4.5t bucket.

“We’re looking at reducing diesel use any way we can”

Fulton Hogan’s 9,000 employees across 100 locations deliver critical infrastructure projects and develop products including asphalt, biodiesel and concrete. The company places an emphasis on sustainability and emissions reduction.

Manufacturing, Product and Sales Manager Wayne Richardson says, “We used to use a lot of diesel here, with all our plant, so we’ve looked at reducing that right down in every way we can.”

The loader is not their first piece of electric equipment. In late 2022 the Reliable Way plant introduced the Southern Hemisphere’s first Keestrack electric crusher and a 30-tonne hybrid Volvo EC300EL excavator.

We get a full charge in 80 minutes or so, and we get an 8-hour shift out of the loader.

80 minutes’ charge for an 8-hour shift

The electric loader’s battery lasted longer than the team anticipated. Because of this there was no need to change work scheduling to accommodate charging, as it could be fully charged overnight.

The site’s 240kW charging station can fully charge the JL120’s 282kWh battery in around 80 minutes.

During the December-April trial period, there were only two shifts that were longer than usual, where the machine needed a top up. During these times, the charger can provide a 42% recharge to the battery during a 30-minute break.

There were some initial teething issues with charging the loader, as plugging it in would trip fuses on the site. However, after upgrading the fuse board, they have had no further issues.

The electric machine is a favourite with drivers

Operators found the JL120 quieter, more responsive than a diesel L120H, with smoother and faster gear changing and with power equivalent to a L120H.

The machine’s quietness is also important given Reliable Way’s residential neighbours.

Wayne is clear the machine is a win-win-win. “All the boys are on board. If there’s a choice now, they’d far rather jump in the electric loader than the diesel. Quieter, smoother, gruntier – why wouldn’t you?”

Explore support opportunities

We can help your business become more productive with less energy, and support your switch to renewable energy sources.

Read next

-

Electric off-road machines

Businesses around the country are adopting electric off-road machines – and operators are impressed.

- Electric vehicles

- Decarbonisation

- Case study

-

Decarbonising off-road heavy vehicles in New Zealand

A view of the market for heavy duty, electric machines — now and into the future.

- Electric vehicles

- Market research

- Decarbonisation

-

Electric loader outperforms diesel

Southern Landfill’s electric wheel loader is big on performance, low on noise and operating costs.

- Electric vehicles

- Decarbonisation

- Case study