A cost-effective opportunity to lower transport emissions

Electric trucks are a vital and viable component in New Zealand’s effort to reduce its emissions in the transport sector to help it transition to a greener future.

Several companies in New Zealand have been trialling electric trucks in their transport operations in a number of different applications. These trials show that electric trucks have the potential to achieve considerable operational savings whilst also removing emissions off New Zealand’s roads.

Grants are now available reducing the purchase price of electric trucks by up to 25%, to support businesses taking the lead.

On this page:

- Benefits of electric trucks

- Is it time for battery electric trucks to start powering your fleet?

- Types of battery electric trucks

- Charging options

- Charging time

- Total cost of ownership

- EECA's Low Emissions Heavy Vehicle Fund

- What uses are e-trucks best suited for?

- Considerations when selecting electric trucks

- Feasibility considerations

- Energy supply and infrastructure

- Useful tools

Benefits of electric trucks

- Zero emissions – Electric trucks produce zero tailpipe emissions. With New Zealand’s power grid being about 80-85% renewable, powering these trucks results in very low emissions.

- Lower fuel costs – Electricity is cheaper than diesel, making electric trucks significantly cheaper to run.

- Lower maintenance costs – Electric trucks cost less to maintain because they have fewer moving parts. This leads to fewer repairs and less downtime, allowing the truck to stay on the road longer and generate more income for the operator.

- More energy efficient – Electric motors are more efficient, converting over 90% of energy into motion, compared to just 30-40% for internal combustion engines. This allows electric trucks to travel farther on the same amount of energy.

- Quieter – The absence of engine noise makes e-trucks particularly suitable for urban areas and night-time deliveries, reducing noise pollution.

- Regenerative braking – Regenerative braking captures and converts kinetic energy from vehicle braking into electricity. This energy is then transferred and stored in the battery and can be used to power the truck, increasing the vehicle's range.

- Improved driver experience – Electric trucks are quieter and have less vibration, making driving more comfortable and reducing fatigue. Their instant torque and quick acceleration improve handling, especially in stop-and-go situations like urban deliveries. This smoother power delivery also gives drivers better control and helps reduce fatigue.

- Green image – As consumers and businesses become more focused on reducing carbon emissions, demand for low-emissions freight will grow. By opting for electric trucks, companies can stay ahead of this trend and demonstrate their commitment to cutting emissions and fighting climate change.

Is it time for battery electric trucks to start powering your fleet?

In recent years, battery electric trucks have emerged as a transformative force in transportation as a clean and energy efficient means of transporting goods, and are going to be a key means to reduce New Zealand’s transport sector emissions.

Several New Zealand companies are already trialling electric trucks in their transport fleets, ranging from last-mile delivery light commercial vehicles, through to more heavy-duty trucks for medium haul, point-to-point transport. These early adopters are gaining valuable insights into the technology while standing out as leaders in low-carbon transport. They're also seeing lower operational costs due to reduced fuel and maintenance expenses.

Today's electric trucks can travel up to 350km on a single charge, with some models claiming 600km, reducing range anxiety. Charging times are also improving, with faster charging options of up to 300kW now widely available to purchase and install in depots, and increasingly offered at public charging stations throughout New Zealand. New charging standards are on the horizon that will allow charging times to be reduced further.

The electric truck market is now mature enough to cater to many trucking purposes and is quickly growing, though certain applications offer more upside than others and should be considered when assessing the viability of electric trucks for your fleet.

EECA’s Low Emissions Heavy Vehicle Fund is offering grants of up to 25% of the purchase price of new battery electric or hydrogen fuel cell electric, or 25% of the cost of converting existing, recently purchased diesel trucks to zero or low-emissions technologies. Terms and conditions apply.

Cheaper electric transport is coming, and how we transition our fleet is important. It’s time to consider how we go from the traditional model to the new model…the future is here, the change is happening. Let’s get on with it and experiment.

Types of battery electric trucks

Battery electric trucks operate on the same principle as battery electric cars, just at a larger scale – energy is stored in a battery to power an electric motor which propels the vehicle. Battery packs are typically located in the chassis of the truck, or underneath the vehicle.

Electric trucks use lithium-ion batteries which are well-suited due to their high energy density and rechargeability. This is used to power one or more electric motors which are connected to the vehicle’s drivetrain which transfers power to the wheels.

There are currently two main types of battery electric trucks available in the market:

- Standard battery – Standard battery electric trucks have a fixed battery that remains on the vehicle at all times. They use conventional stationary wired charging to charge from an external power source, such as a charging station or electric outlet. Charging options include standard alternating current (AC) charging or faster direct current (DC) charging stations depending on the vehicle type.

- Battery swap – Battery swap electric trucks use detachable modular batteries that allow operators to quickly replace a depleted battery pack with a fully charged one. The battery packs are usually located behind the truck’s cabin. These batteries can also be charged via traditional wired charging whilst still connected to the truck. Compared with wired stationary charging, battery swapping technology could significantly shorten the time required to recharge electric vehicles.

Charging options

When considering an electric truck, charging options and battery size should be factored in from a cost, feasibility, and flexibility perspective.

There is no one-size-fits all for the right mix of charging options for operators, as it depends greatly on the type of operation, daily mileage and the size of their fleet. However, the range of different charging options enables operators to adopt different charging strategies to optimise charging for their use-case and certain charging options cater better to different route types, whether they be fixed, point-to-point or ad hoc.

MCS – the future of public truck charging hubs

The megawatt charging system (MCS) is a new charging standard that will enable charging rates of over a megawatt and is expected to be available in New Zealand by 2025. This new standard will enable a significant reduction in charging times.

MCS has been ratified and agreed among manufacturers and will likely become the industry standard for electric trucks. As operators' fleets become increasingly electrified and newer charging standards such as megawatt charging are rolled out, we are likely to see installation of shared stations at convenient mid-route locations, with capacity to charge multiple trucks at once at up to 2MW.

These shared stations will be essential as it will not be viable or financially feasible for many operators to get enough electricity supply to their private depots to power the MCS chargers and recharge their electric fleet.

Charging time

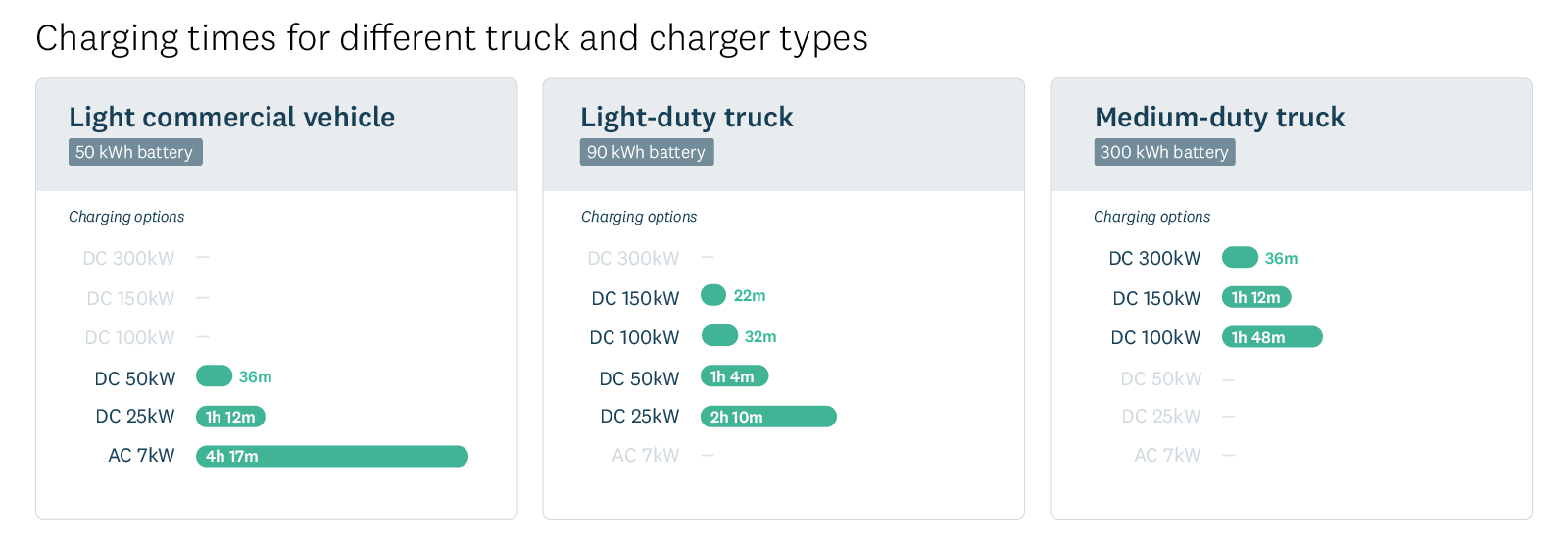

The time required to charge an electric truck largely depends on the charging rate and the battery's capacity but can also be influenced by factors such as the truck’s battery management system and temperature.

Light commercial vehicles used in single-shift, short-medium haul daily operations can be charged overnight with slower AC charging. Medium and larger, heavy-duty trucks require faster DC charging. Their battery packs are considerably larger (up to 625kWh), and there will be insufficient time overnight for AC charging to fully charge the vehicle.

For some trucks with larger battery capacities, it is possible to use dual or multiple chargers at once to reduce charging time.

The chart below highlights the estimated charging times across three different weight classes and the most fit-for-purpose charging options. These range from slow 7kW AC charging right up to the fastest widely available charging of the 300kW DC chargers. Charging options that are not feasible have not been included in the chart, for example most light commercial vehicles do not currently allow for 300kW DC charging, and 7kW AC charging would be too slow to be considered for heavy-duty trucks.

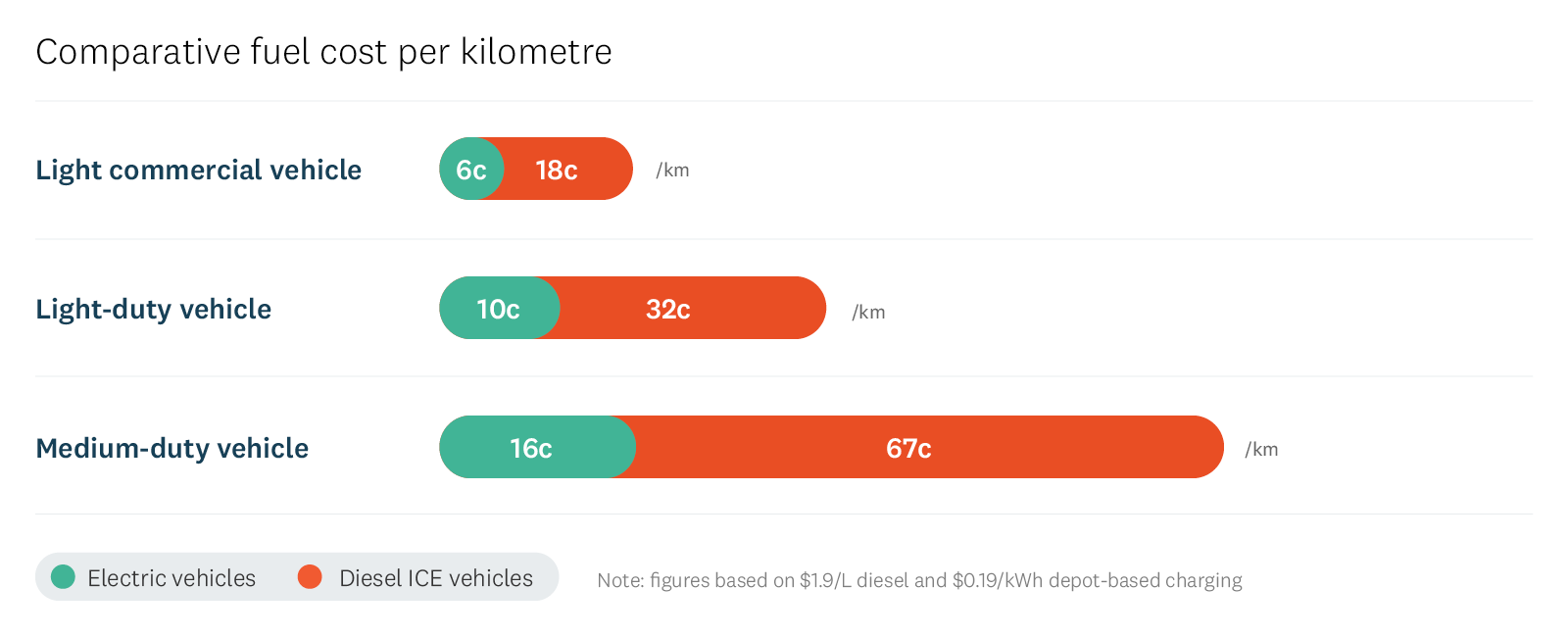

Total cost of ownership

Today, the total cost of ownership (TCO) of electric trucks has reached parity with internal combustion engine (ICE) vehicles in certain applications. EV technology and infrastructure are rapidly advancing, becoming increasingly more cost-effective and accessible in New Zealand.

This, coupled with a supportive regulatory environment in New Zealand, such as EECA’s new Low Emissions Heavy Vehicle Fund (LEHVF) and an exemption from road user charges for heavy electric vehicles until 31 December 2025, means that there is now more incentive than ever to adopt electric trucks into transport fleets.

The charts below highlight the favourable comparative cost per kilometre for fuel costs across three different electric vehicle weight classes.

The TCO equation for electric trucks is predicted to improve further over time. Boston Consulting Group predicts that the TCO of electric trucks will attain parity with traditional ICE vehicles across all applications by 2025, as battery costs continue to decrease.

Purchase costs and resale value

The upfront cost of an electric truck is substantially higher than that of an ICE equivalent. This includes purchasing the vehicle(s), installing charging stations and necessary transmission upgrades to accommodate them when necessary.

One other factor to consider when making TCO calculations is residual value and resale. As this is an emerging technology, electric trucks do not currently have a mature second-hand market. It is therefore difficult to predict the residual value of an electric truck.

Model your own total cost of ownership

Ara Ake has created a free comparison tool to help long-distance heavy freight companies better understand the options for decarbonising their road fleet. The tool takes a ‘total cost of ownership’ (TCO) approach to calculating the cost of road freight movements. It allows users to run their own scenarios and input their own data.

EECA’s Low Emissions Heavy Vehicle Fund

The Low Emissions Heavy Vehicle Fund (LEHVF) aims to increase the number of zero and low-emissions heavy vehicles on New Zealand’s roads, and provide market signals to manufacturers to encourage supply.

Grants cover up to 25% of the purchase price of low emissions heavy vehicles, and will be available until 2028, unless available funds run out sooner.

What uses are e-trucks best suited for?

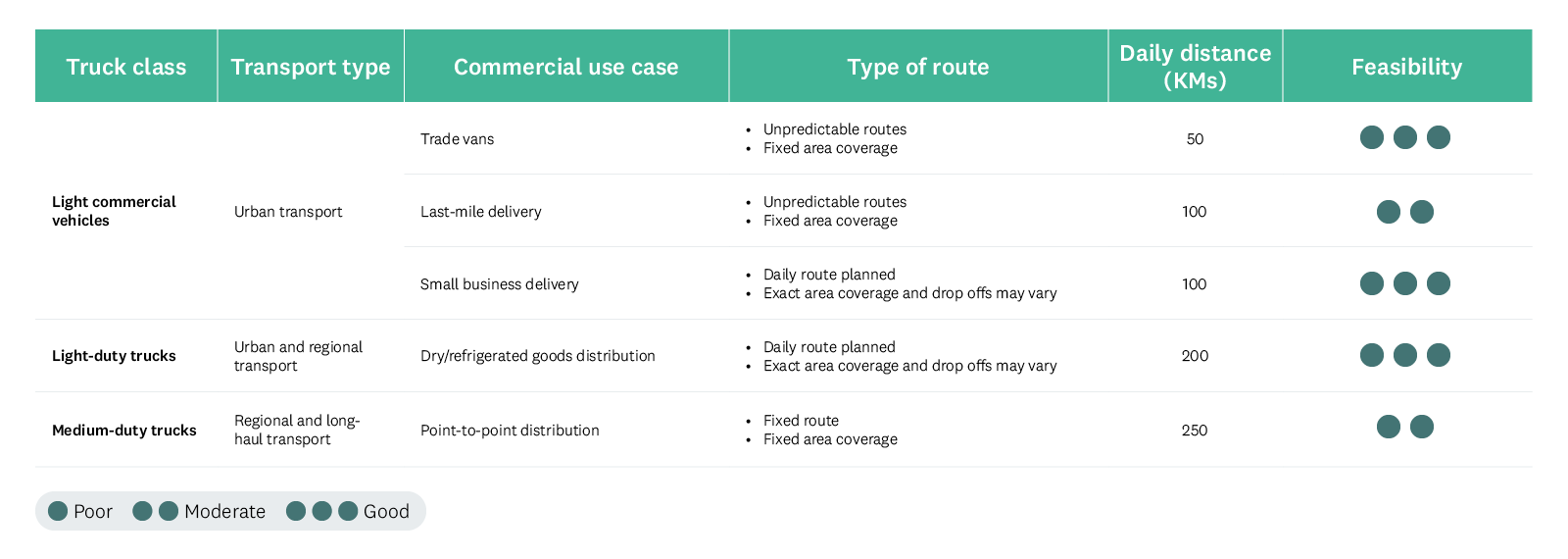

Currently, electric trucks are more practical for certain use-cases and route types. This feasibility summary takes into account the availability of battery chargers, travel distance, predictability of the route and payload capacity of the vehicle.

The most favourable applications for electric vehicle transport uses are routes that are:

- Planned or predictable

- Shorter or fixed distances

- Transport volume rather than weight-dependent freight

The table below highlights the current feasibility of electric trucks for different use cases. Below this, we investigate case studies where companies are already using electric vehicles for the following use cases:

- Light commercial vehicles making last-mile deliveries

- Medium-duty vehicles distributing dry goods

- Heavy-duty vehicles performing point-to-point medium-haul operations

Light commercial vehicles making last-mile deliveries

These small, lightweight trucks or vans commonly cover short distances, usually under 100km per day. They tend to transport light packages without the need for refrigeration such as couriers or small goods distribution.

Modern batteries efficiently power these vehicles, even when fully loaded, and have sufficient capacity to complete most routes with no need for mid-route charging.

Light-duty trucks distributing dry goods

Light-duty trucks are a feasible application for electric trucks, particularly for the distribution of dry goods within cities. These trucks typically transport goods from large warehouses to urban supermarkets, stores or distribution centres.

With predetermined routes less than 200km, these trucks can be charged overnight, without the need for charging during operation throughout the day.

Medium-duty trucks for mid-distance transport

Medium-duty trucks are best suited for uses where the routes and distances are highly predictable and fixed, spanning a range of 200 to 300km. Most battery recharging would be done overnight, but batteries can also be topped up during driver breaks. To be fully charged overnight, they require fast DC charging.

Considerations when selecting electric trucks

- Capital cost – Electric trucks typically have a higher upfront cost compared to conventional ICE trucks. The cost of batteries, electric drivetrain components, and the overall technology involved in electric vehicles can contribute to higher purchase prices. It is important to note that technology advances are improving the efficiency of battery solutions, which are driving down the cost and making greater adoption more feasible at a more attractive price point. Selecting the right electric truck, with the right battery capacity can also help keep prices lower.

- Model availability – While the availability of electric truck models is increasing, it may not cover all the different sizes, configurations, and specialised applications that conventional trucks offer. The availability of models is expected to expand significantly in the near-future, with some estimates that vehicle manufacturers could offer around 50 zero-emissions models by 2025, though all of these may not be available in New Zealand.

- Range – Electric trucks typically have a lower driving range compared to ICE vehicles. Although battery technology is improving, electric trucks may require more frequent charging or have shorter operational distances, which can be a limitation for long-haul, unpredictable, or heavy-duty applications.

- Battery weight – The weight of the battery pack reduces the amount of cargo the truck can carry, which may be a limitation in certain applications where maximising payload is critical. Additional weight from the batteries is an important consideration for operators when determining their electric truck axle-set configurations and limits.

- Battery capacity - Battery weight also tends to be strongly linked to the battery’s capacity. Many original equipment manufacturers (OEMs) offer varying battery configurations and capacities for their truck builds to accommodate a range of operator requirements. Working with the OEM to determine the optimal battery capacity for your truck can help to ensure the truck’s configuration is fit for purpose. They can help ensure the truck’s configuration is efficient, so that it has enough range for its task, and is not carrying additional battery weight it may not need, and that the operator is not paying for more battery than it needs.

- Refuelling time – The time needed to recharge can lead to longer downtimes, affecting the overall efficiency of operations. Emerging technologies such as battery swapping offer a promising alternative that can significantly reduce downtime.

Feasibility considerations

Other things to consider when assessing electric truck feasibility for your fleet.

- Freight capacity – Shifting goods that are volume-limited means that there are fewer consequences of the electric truck’s heavier weight. In comparison, weight-limited freight is less favourable for electric vehicles, where every tonne of vehicle powertrain weight reduces haul capacity.

- Fleet size – Operators with large fleets have an advantage when adopting electric trucks, as it means it is more economical to test and scale electric trucks in their fleet and install charging stations. Operators with smaller fleets who are adopting electric trucks may have less capital to invest upfront, and any introduction of electric trucks could have a relatively greater impact on operations that would need to be considered.

- Owner-operator drivers – Businesses that rely on owner-operator drivers have less flexibility around how they can implement electric trucks into their fleets, as they have less control over the fleet’s composition. For owner-operator drivers, the initial capital cost of an electric truck may be too high to take on, meaning that there may be greater hesitancy to adopt them. While freight companies could update their cost models to reflect the high CapEx/low OpEx nature of electric trucks, owner-operators are likely to have less access to finance to fund the initial capital outlay. Owner-operators are also less likely to install their own charging infrastructure, so will look to utilise shared chargers at the operator’s depot or public charging, which will likely come at a higher OpEx cost for them.

- Route optimisation – This is a key consideration for getting the most out of an electric truck’s range, and it is important for operators to consider how best to optimise the trucks’ payload planning, battery management, total route elevation, and charging. It is also valuable to upskill drivers to adopt energy-efficient driving habits, such as avoiding hard acceleration and braking, maintaining a steady speed, and using regenerative braking when available.

- Shift optimisation – Related to route optimisation is the need to also consider how best to optimise drivers’ shifts. Drivers will need to consider when is best for them to take their breaks, whether charging will be required during this time, and if so, whether they have easy access to a charger whether that be depot-based or mid-route. If the electric truck is used for multi-shift routes, then operators will also need to ensure that time and charging options are accounted for to charge the truck between shifts.

- Maintenance facilities and technicians – As electric trucks are still an emerging technology, there are currently a limited number of service centres or roadside assistance agencies with the capability to service them. In addition, in-house maintenance technicians will need to be re-trained to be able to service the vehicles.

Energy supply and infrastructure

In most instances, it will be necessary for transport operators to install charging infrastructure at their depots. In many cases, transmission upgrades will be required to supply adequate electricity, which increases the cost of installation.

- Understand your energy supply early – For some depots, even adopting a small number of electric trucks will mean that their depot will need significant electrical upgrades to supply power to the chargers. The first step for operators when considering a transition to electric trucks is to contact their local energy providers to ascertain how much energy supply is currently possible. It may also be necessary to undertake an energy audit to understand to what extent electrification is possible, and what electrical and infrastructure upgrades may be required.

- Engage with your original equipment manufacturers – Operators should work with both the vehicle and charger manufacturers throughout the process to ensure that the electrical charging is set up correctly and is best suited to the requirements of the electric truck, charger, and charging times.

- Plan for expansion – Whilst a fleet’s electrification journey may start with just a small number of trial vehicles, it may be worth ensuring that any infrastructure upgrades to things such as transformers, conduit and switch gears are future-proofed to provide sufficient energy to support future electric truck charging requirements. For operators that may electrify heavy trucks this is especially important, as newer high-demand charging standards, such the MCS, will likely become the standard in the near-future and will have significant electricity demand. In some instances, it may be feasible to install a microgrid, or onsite-generation to ensure enough energy supply now and into the future. Consulting on future energy demand early has the potential to save money down the line.

- Public charging – There are over 600 public chargers in New Zealand that can accommodate light commercial vehicles. Whilst charging stations are increasing in number, especially in urban areas, the limit of current network can pose challenges for long-distance travel or in more remote areas. In addition, charging infrastructure that supports the larger vehicle size of medium and heavy-duty electric trucks is currently much more limited. These factors should be considered by fleet managers when assessing charging options for their fleet.

Useful tools

EROAD fleet management tool

EROAD has developed a web-based vehicle emissions calculator tailored for New Zealand fleets. The tool aims to empower businesses in their journey towards decarbonisation and environmental responsibility. It is free and available to any business with, or without existing GPS vehicle tracking systems and those utilising telematics services from other providers.

EROAD Emissions Calculator(external link)

SwitchMyFleet

SwitchMyFleet, an online tool from Critchlow Geospatial, that aims to help businesses electrify the way they transport their goods. It is a free online tool for businesses and fleet managers who are considering switching some or all of their vans and small or medium trucks to electric. Using real-world business scenarios that are specified by the user, the tool forecasts the operating costs of internal combustion engine (ICE) and commercial electric vehicles (EVs).

Ara Ake TCO tool

Ara Ake has a free comparison tool to help long-distance heavy freight companies better understand the options for decarbonising their road fleet. The tool takes a ‘total cost of ownership’ (TCO) approach to calculating the cost of road freight movements. It allows users to run their own scenarios and input their own data.

Read next

-

Low Emissions Heavy Vehicle Fund

Accelerating the uptake of zero and low-emissions heavy vehicles.

- Co-funding

- Electric vehicles

- Decarbonisation

-

Electric vehicles and Aotearoa

Electric vehicles make up a small portion of our total fleet now, but that is going to change.

- Electric vehicles

-

Hydrogen haulers: how heavy transport is lowering its emissions

Two New Zealand companies are trialling different hydrogen technologies in an effort to lower transport emissions.

- Case study

- Hydrogen

- Co-funding